Truck driver safety isn’t just about following rules-it’s about getting home alive. Every year, large truck accidents kill thousands of people on American roads, and many of these crashes are preventable.

We at DriverEducators.com know that drivers face real challenges: fatigue, distractions, and equipment failures. This guide covers the proven practices and technologies that actually reduce accidents.

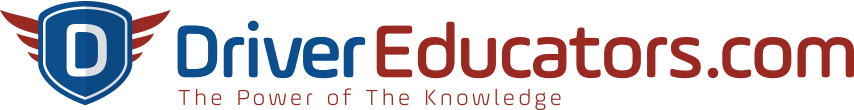

What Really Causes Truck Accidents

Fatigue Impairs Judgment and Reaction Time

Fatigue kills drivers and destroys lives. According to the Federal Motor Carrier Safety Administration, driver fatigue ranks among the leading causes of commercial vehicle crashes, and it remains preventable. The FMCSA requires electronic logging devices to track hours of service, yet violations persist because drivers push beyond safe limits to meet delivery schedules. A driver operating after 14 consecutive hours of availability-the legal threshold before mandatory rest-experiences impaired judgment and slower reaction times comparable to driving under the influence.

Following hours-of-service rules strictly, taking mandatory breaks every three to four hours, and prioritizing sleep form the foundation of fatigue prevention. Many carriers now use ELD data to reinforce compliance, and drivers who respect these limits report fewer accidents and better health outcomes.

Distracted Driving Steals Critical Seconds

Phones, eating, and GPS adjustments cause crashes because they steal critical seconds needed to react to hazards. The FMCSA prohibits texting for CMV drivers, yet distraction remains a leading crash factor. A driver looking at a phone for five seconds while traveling at 55 mph travels the length of a football field without eyes on the road. Hands-free calling with one button is legal; texting and handheld use are not. Employers must enforce strict anti-distracted-driving policies and model safe behavior by avoiding unnecessary calls or texts when drivers operate vehicles. Drivers should turn off the radio in heavy traffic or bad weather, silence phone notifications, and complete all adjustments before moving the vehicle.

Mechanical Failures Create Preventable Hazards

Pre-trip inspections catch problems before they cause accidents. Tire failures, brake defects, and lighting issues account for significant preventable crashes. Drivers should check tires for proper pressure and tread depth, test all brakes for responsiveness, and verify that lights, mirrors, and reflectors work correctly. A shifting or unsecured load can cause loss of control or rollover; inspecting load securement and weight distribution before every trip prevents these incidents. Post-trip inspections matter equally-drivers must report defects immediately to leadership so the next operator doesn’t inherit a dangerous vehicle. Fleets that invest in proactive maintenance programs and clear reporting systems see accident rates drop sharply because mechanical problems get fixed before they harm someone on the road.

These three factors-fatigue, distraction, and mechanical failure-account for the majority of preventable truck accidents. Understanding what causes crashes sets the stage for implementing the defensive driving techniques and safety practices that actually stop them from happening.

Essential Safety Practices for Truck Drivers

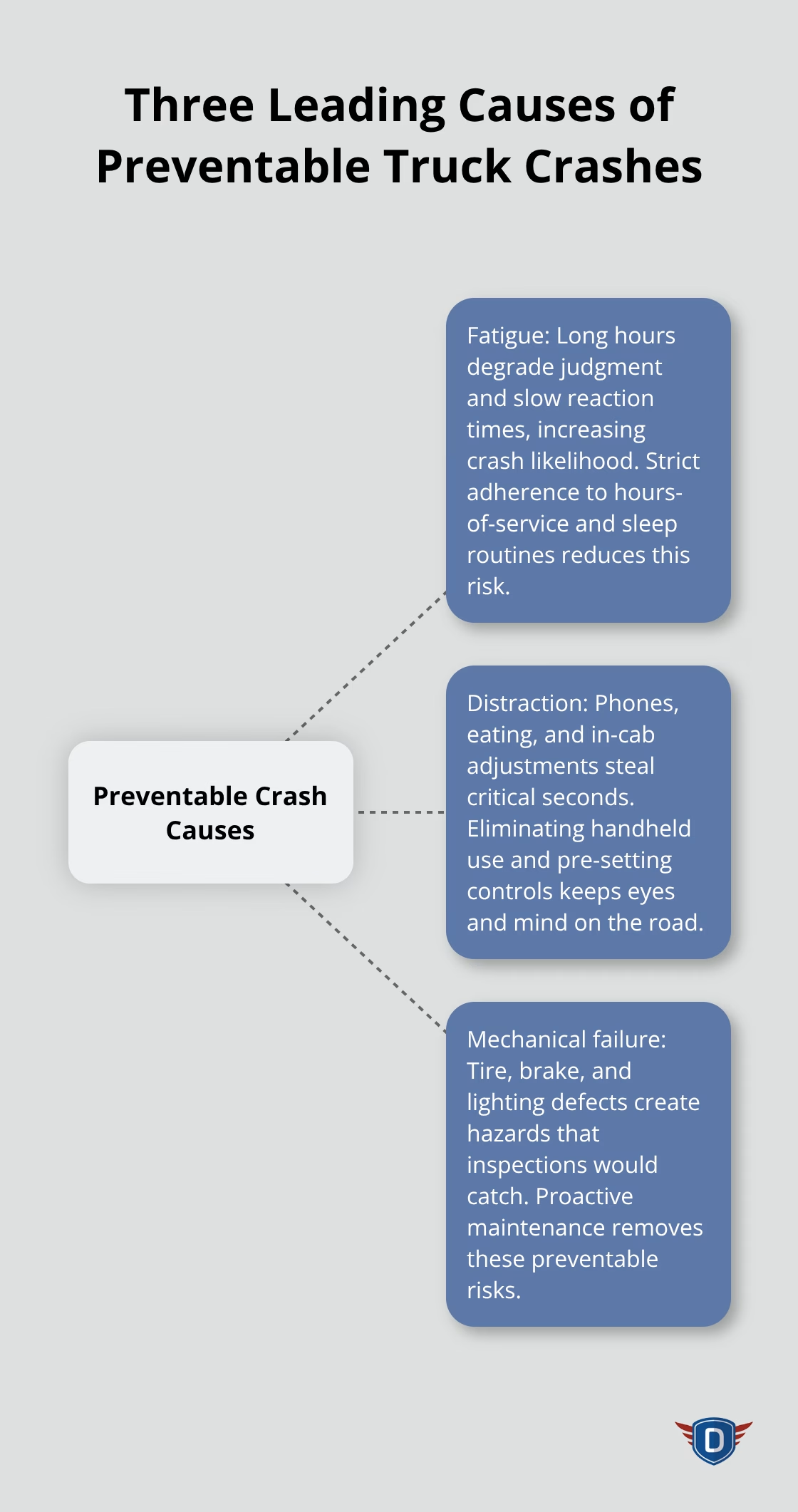

Pre-Trip Inspections Catch Problems Before They Become Disasters

Thorough inspections before every trip stop mechanical problems from becoming roadside disasters or fatal crashes. A driver should spend 10 to 15 minutes checking tires for proper pressure and tread depth, testing brake responsiveness by applying firm pressure before moving, verifying that all lights and reflectors function, and confirming that mirrors are clean and properly adjusted.

Load securement matters as much as vehicle condition-a shifting load causes loss of control or rollover, and these incidents often prove fatal. Check that cargo sits balanced across the trailer, that tie-downs stay tight and secure, and that nothing rests against doors or can move during braking or turning. Many drivers skip post-trip inspections, but this step ensures defects get reported so the next operator doesn’t inherit a broken truck. A driver who finds a problem must report it immediately to leadership rather than hoping it fixes itself or assuming the next shift will handle it. Pre-trip inspections catch mechanical problems before they cause accidents, so fleets that enforce clear inspection protocols and reward drivers for catching problems early see accident rates drop because mechanical failures get fixed before they harm anyone.

Defensive Awareness Identifies Hazards Before They Strike

Defensive awareness means scanning ahead 15 seconds and checking mirrors every 8-10 seconds to identify vehicles in blind spots and anticipate hazards before they become emergencies. Trucks have massive no-zones on all sides-areas where other vehicles disappear from view-and drivers must maintain deliberate awareness of what surrounds them. Maintain a seven to eight second following distance behind other vehicles, extending to 14 seconds or more in rain, snow, or fog because trucks require significantly longer stopping distances than passenger vehicles. When changing lanes or turning, signal at least three seconds in advance and complete the maneuver slowly over about seven seconds to remain predictable to other drivers. Speed control proves equally critical-trucks accelerate slowly uphill and gain speed quickly downhill, so adjust speed for road grade, weather, and conditions rather than maintaining constant speed regardless of circumstances. Avoid the temptation to rush deliveries by exceeding safe speeds; speeding increases crash risk and removes the reaction time needed to avoid hazards. Many accidents happen because drivers underestimate how long trucks need to stop or misjudge how quickly downhill momentum builds, so respect the physics of your vehicle rather than fighting it.

Load Management Prevents Loss of Control

Proper load management stops accidents that stem from cargo shifting or weight imbalance. A driver must verify that cargo distributes evenly across the trailer bed, with heavier items positioned low and centered to maintain stability during turns and braking. Tie-downs must stay tight and secure-loose straps allow cargo to shift, which can cause the truck to tip or lose traction on curves. Nothing should rest against trailer doors or hang over the sides, as these conditions create hazards for other vehicles and increase rollover risk. Drivers who inspect load securement before departure and report any concerns to dispatch prevent incidents that could kill someone on the road. Fleets that implement clear load-securement procedures and train drivers on weight distribution see measurably fewer accidents because cargo stays where it belongs, and the truck handles predictably under all conditions.

The combination of rigorous inspections, heightened awareness, and proper load control forms the foundation of accident prevention. These practices work because they address the mechanical and human factors that cause crashes. Technology now amplifies these efforts-advanced systems monitor driver behavior, track vehicle health in real time, and alert operators to emerging risks before they escalate into collisions.

How Modern Fleets Track Driver Behavior and Prevent Crashes

Telematics Systems Monitor Real-Time Driver Performance

Telematics systems monitor what happens in the cab and on the road in real time, giving fleet managers the data they need to stop accidents before they happen. These systems track acceleration, braking patterns, cornering speed, following distance, and lane departures, then alert drivers immediately when they exceed safe thresholds. A driver who brakes hard suddenly, takes a curve too fast, or drifts between lanes receives instant feedback through in-cab alerts or post-trip coaching from their manager. This matters because behavior change follows data-driven feedback far more reliably than general safety lectures. The FMCSA uses seven Behavior Analysis and Safety Improvement Categories, called BASICs, scored on a 0–100 scale where 100 indicates the worst performance, enabling carriers to track safety metrics across their entire fleet. Fleets that invest in telematics systems see measurable improvements in these scores because drivers know their actions are monitored and they receive specific, actionable coaching on what to change.

Fatigue Detection Systems Prevent Drowsy Driving Crashes

Fatigue detection systems now integrate with telematics to identify when drivers show warning signs of drowsiness-slower reaction times, micro-sleep episodes, or erratic steering patterns-and alert them to pull over and rest before fatigue causes a crash. These systems work by analyzing steering input, lane position, and eye closure patterns captured through in-cab cameras, then flagging high-risk periods before the driver becomes dangerously impaired. A driver receiving a fatigue alert at mile 200 of a long haul can pull into a truck stop, nap for 30 minutes, and arrive at their destination safely rather than fighting to stay awake and risking a catastrophic collision.

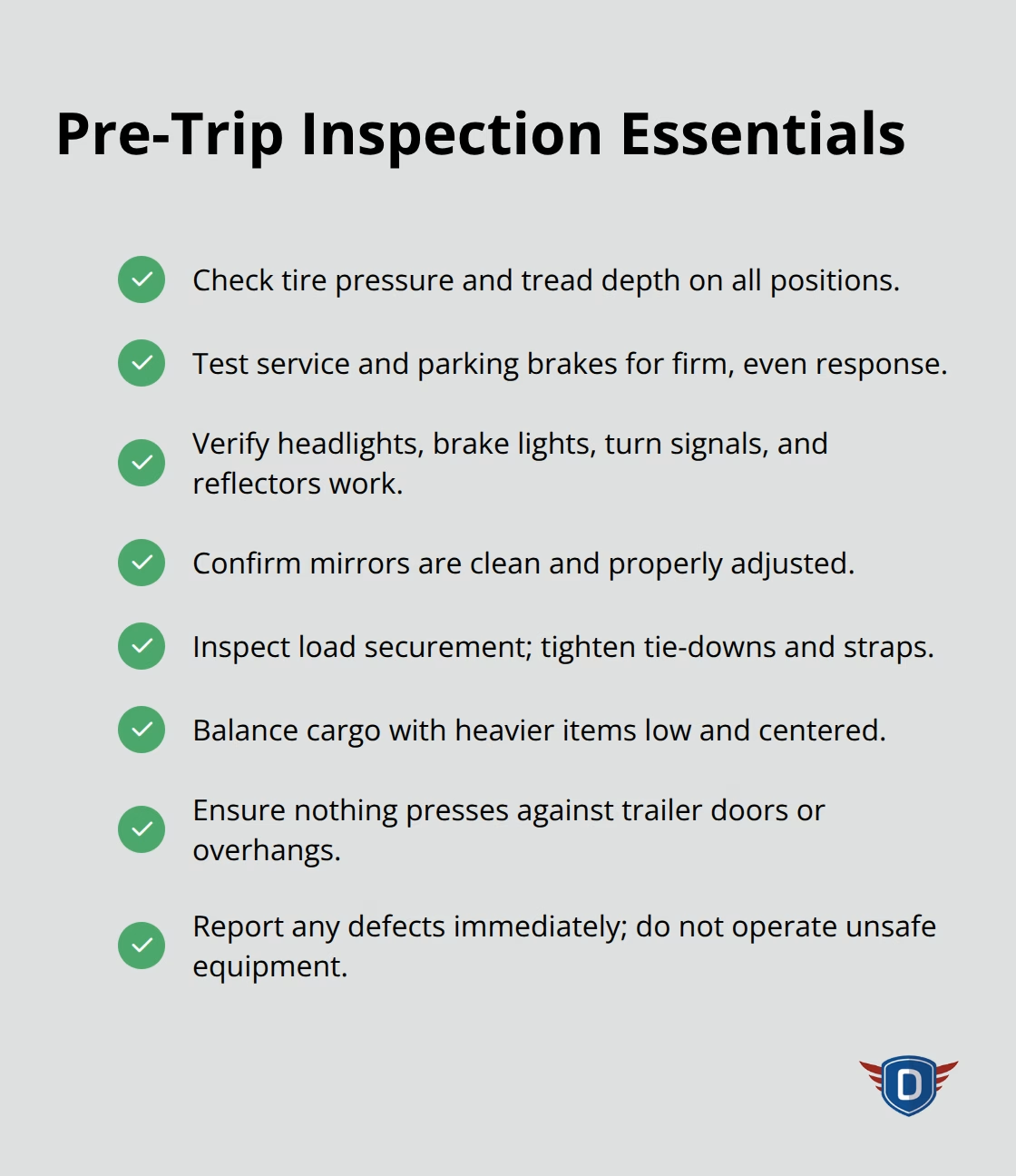

Collision Avoidance Technology Reduces Crash Risk

Collision avoidance systems have become standard equipment on new commercial trucks, and they work by detecting vehicles, pedestrians, and obstacles ahead and automatically applying brakes if the driver fails to respond. Automatic emergency braking prevents rear-end collisions and reduces crash risk by 12% overall and 41% for rear-end crashes, while forward-collision warning systems give drivers several seconds of advance notice to react. Blind-spot detection systems alert drivers when vehicles enter no-zones on either side or behind the truck, eliminating the most dangerous accidents caused by lane changes into unseen traffic.

Lane-departure warning systems vibrate the seat or steering wheel when a truck drifts out of its lane, catching drowsy drivers before they cross into oncoming traffic or jackknife. These systems provide a mechanical safety net when human attention lapses.

Technology Investment Pays for Itself Through Reduced Claims

The cost of installing these systems-typically $3,000 to $8,000 per truck-pays for itself within two to three years through reduced accident claims, lower insurance premiums, and fewer days out of service for repairs. Fleets that equip their trucks with collision avoidance and telematics systems report accident reductions of 20 to 50 percent depending on the technology package and driver compliance with coaching feedback. The key is not just installing the technology but using the data it generates to coach drivers on specific behaviors that reduce risk, making safety part of the fleet culture rather than a compliance box to check.

Final Thoughts

Truck driver safety improves when fleets combine proven practices with modern technology. The foundation remains unchanged: rigorous pre-trip inspections, defensive awareness, and proper load management stop accidents before they happen. These practices work because they address the root causes of crashes-fatigue, distraction, and mechanical failure-by giving drivers the tools and discipline to prevent them. Technology amplifies human effort, with telematics systems providing real-time feedback that changes driver behavior faster than lectures ever could, while fatigue detection systems catch drowsiness before it becomes deadly.

The financial case is clear: installing collision avoidance and telematics systems costs $3,000 to $8,000 per truck but pays for itself through reduced claims, lower insurance premiums, and fewer repair days. More importantly, these investments save lives-every accident prevented means a driver goes home to their family, and every prevented crash removes risk from the roads for everyone. The FMCSA BASICs framework gives fleets measurable metrics to track progress, and carriers investing in these systems report accident reductions of 20 to 50 percent within two to three years.

Truck driver safety requires ongoing commitment from drivers, fleets, and technology working together toward one goal: getting everyone home alive. Drivers must stay current on regulations and refresh their skills regularly, while fleets must model safe behavior, enforce clear policies, and use data to coach drivers toward better decisions. We at DriverEducators.com provide comprehensive driver education programs designed to build these habits and keep safety at the forefront of every driver’s mind.