Road work zones claim lives every year. According to the Federal Highway Administration, over 5,000 workers are injured annually in work zones across the United States.

We at DriverEducators.com know that road work safety depends on both workers and drivers understanding their responsibilities. When everyone follows proper protocols, accidents drop significantly and projects finish without tragedy.

What Makes Road Work Zones So Dangerous

The Collision of Two Worlds

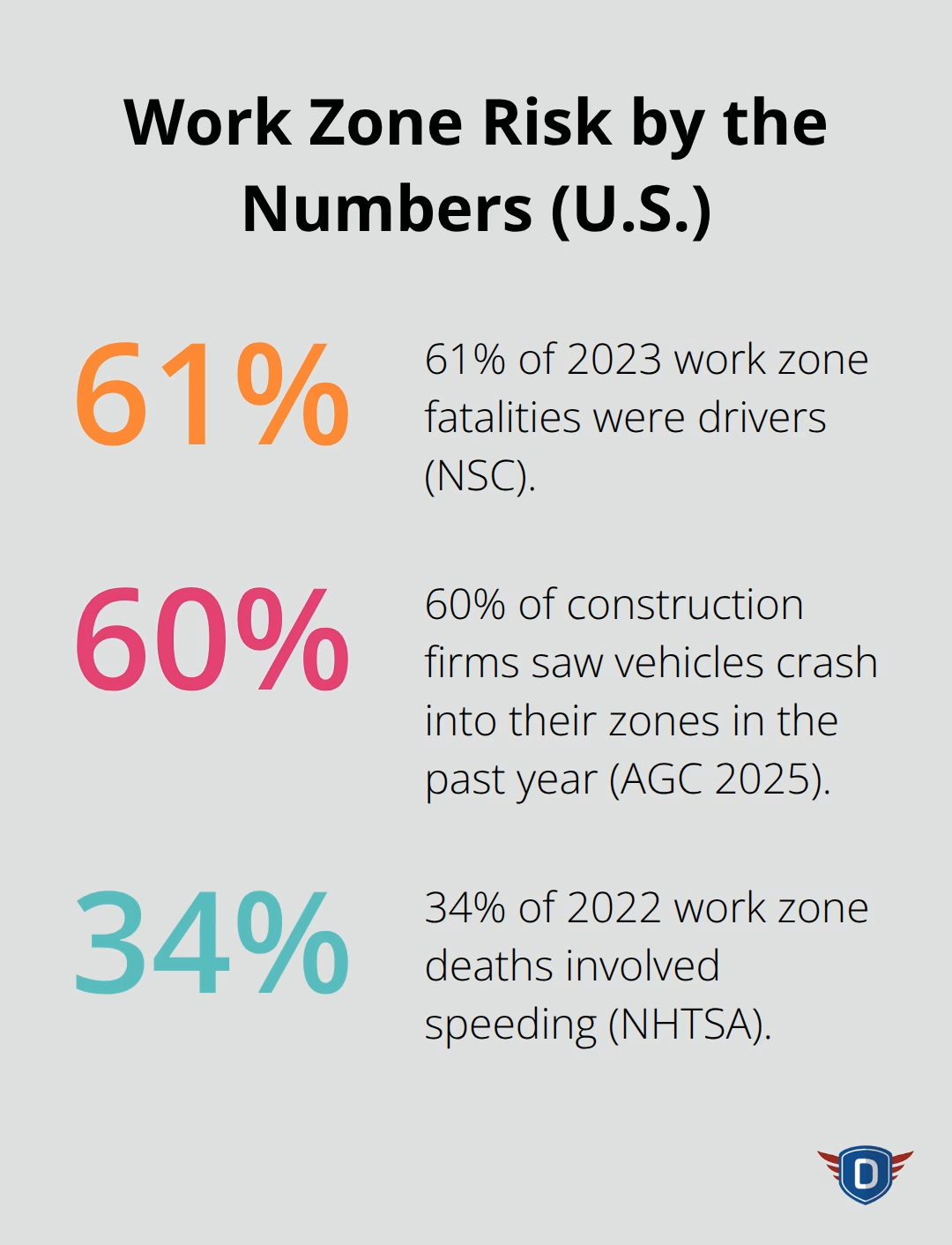

Work zones present hazards that most drivers and workers never fully appreciate until they witness a crash firsthand. The National Safety Council reports that in 2023 alone, work zone crashes killed 898 people and injured 40,170 across the United States. Construction zones accounted for 568 of those deaths, while maintenance and utility zones claimed additional lives. These numbers reveal a hard truth: work zones rank among the most dangerous environments on American roads. The primary threat stems from the collision of two opposing forces-workers focused on their tasks and drivers navigating unfamiliar traffic patterns at high speeds.

The Commercial Vehicle Problem

Large trucks and buses amplify this danger significantly because they have limited maneuverability and expansive blind spots that make detecting workers nearly impossible. When a commercial vehicle enters a work zone, the operator’s ability to react to sudden changes diminishes dramatically. The Federal Motor Carrier Safety Administration notes that trucks and buses are disproportionately involved in work zone crashes, underscoring the need for heightened caution around heavy vehicles.

Speed: The Deadliest Factor

Speed remains the deadliest factor in work zone crashes. According to NHTSA data, fatalities where speeding was a factor rose to 34 percent of all work zone deaths in 2022. Drivers often maintain highway speeds through work zones because they underestimate the hazard or fail to notice reduced speed limit signs in advance warning areas. Enforcement of reduced speed limits, supported by speed cameras and radar feedback signs, can significantly reduce these preventable deaths.

Environmental and Operational Hazards

Weather compounds these dangers significantly. Rain reduces visibility and tire grip, making lane transitions treacherous when traffic suddenly narrows. Heat exhaustion affects both workers and drivers-asphalt surfaces can reach temperatures 30 degrees Fahrenheit hotter than surrounding air, impairing judgment and reaction time. Night work, increasingly common to avoid daytime congestion, demands enhanced visibility through lighting and reflective equipment, yet many work zones operate with inadequate illumination.

The Reality of Work Zone Collisions

A 2025 study by the Associated General Contractors of America found that 60 percent of surveyed construction firms reported motor vehicles crashed into their work zones within the past year. These collisions represent failures across multiple layers: inadequate signage, insufficient worker visibility, poor traffic control, and distracted or reckless driving.

The data makes clear that work zone safety cannot rely on any single intervention. Addressing these hazards requires coordinated action from traffic control planners, equipment operators, flaggers, and drivers who understand their critical role in preventing tragedy.

Building Work Zones That Protect Everyone

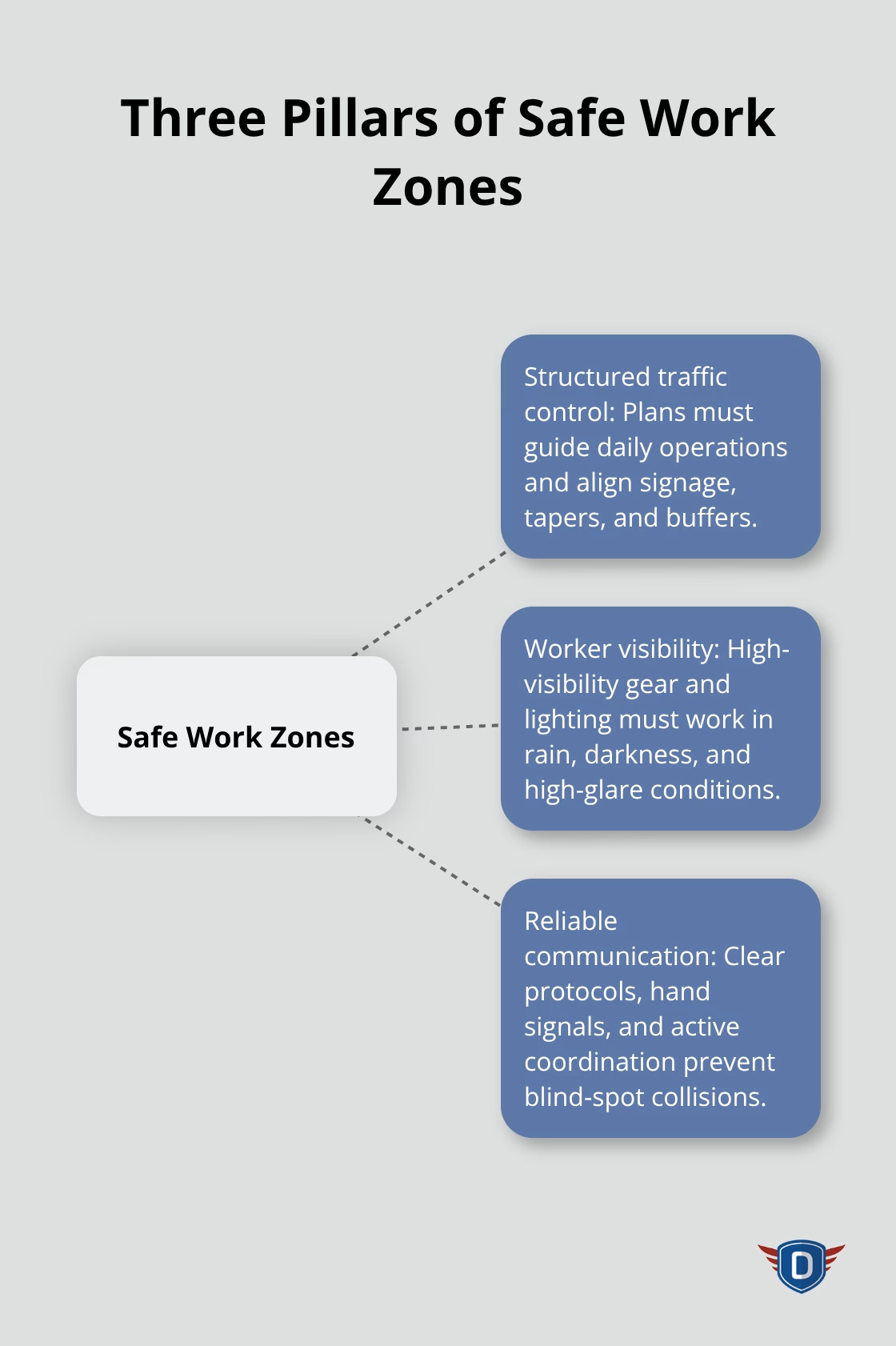

Structuring Work Zones for Maximum Safety

The U.S. Department of Transportation requires a formal Traffic Control Plan for every project, dividing the zone into four distinct areas: Advance Warning, Transition, Activity, and Termination. The Advance Warning area must start at least 0.5 miles before the work zone on highways, using signs or rotating lights to alert drivers well in advance. The Transition area redirects traffic away from the normal path using tapered lanes, while the Activity area contains the actual work space, traffic routes, and buffer zones separating vehicles from workers. The Termination area marks the end with END ROAD WORK signs and posted speed limits to return traffic to normal flow.

This structure works only when executed precisely. Poor placement of warning signs, inadequate taper lengths, or missing buffer zones directly correlate with the crashes we see. Advanced traffic control measures-including clear signage, barriers, cones, and electronic message boards-communicate lane closures and detours in real time. Speed enforcement using cameras and radar feedback signs address work zone safety concerns. Without this structured approach backed by enforcement, drivers navigate work zones unprepared and make dangerous decisions.

Making Workers Visible to Drivers

Worker visibility determines whether drivers spot personnel before impact occurs. Brightly colored fluorescent or reflective vests combined with lighting for night operations save lives, since night work continues growing as a strategy to avoid daytime congestion. Workers must face traffic when possible, with appointed spotters watching for hazards and using mutually understood hand signals in high-noise environments. Equipment operators need seatbelts, direct eye contact with workers before moving vehicles, mirrors and onboard cameras, parking brakes engaged, and strict protocols keeping vehicles within the work zone boundaries.

When workers remain invisible or communication breaks down, collisions become inevitable rather than exceptional.

Establishing Communication That Prevents Crashes

Communication protocols between crews and traffic management require daily safety meetings reviewing scheduled activities, identified hazards, and required protective equipment. Ongoing safety training with strict protocols and compliance incentives creates accountability across all staff. These meetings establish the shared understanding that allows workers and equipment operators to respond quickly to changing conditions.

Equipment operators who make eye contact with workers, use hand signals, and maintain constant awareness prevent the blind spot collisions that kill workers every year. Flaggers positioned strategically throughout the work zone serve as the final line of defense, stopping traffic when workers enter the roadway and resuming flow when the path clears. This human element, supported by training and clear protocols, transforms a work zone from a collision waiting to happen into a coordinated operation where everyone knows their role.

Addressing the Visibility and Communication Gap

The gap between work zones that operate safely and those that fail comes down to whether these three elements function together. Traffic control plans that sit in filing cabinets rather than guide actual operations fail workers and drivers alike. Worker visibility that looks good in daylight but disappears in rain or darkness creates false confidence. Communication protocols that sound good in meetings but break down under pressure leave workers exposed.

Construction firms that invest in all three-structured traffic control, worker visibility, and reliable communication-report dramatically fewer crashes than those treating safety as a checkbox exercise.

The next section examines what drivers must do to navigate work zones safely, recognizing that even perfectly designed and managed work zones depend on driver behavior to prevent tragedy.

What Drivers Must Do in Work Zones

Drivers cause the majority of work zone fatalities. According to the National Safety Council, 61 percent of the 898 people killed in work zones during 2023 were drivers of motor vehicles in transport. This statistic reveals an uncomfortable truth: the most common victims of work zone crashes are the drivers themselves, not workers or pedestrians. Most drivers enter work zones unprepared because they treat them as minor inconveniences rather than genuinely hazardous environments that require tactical changes to driving behavior.

Speed Control Saves Lives

The Federal Motor Carrier Safety Administration recommends reducing speed immediately upon entering a work zone, yet many drivers maintain highway speeds because they fail to notice advance warning signs placed 0.5 miles before the zone or dismiss reduced speed limits as unnecessary. Speed enforcement using radar feedback signs and cameras has proven effective at changing driver behavior, but only when drivers see consequences for violations. Drivers who maintain highway speeds through work zones create collision scenarios that kill both themselves and workers.

Eliminating Distractions in Work Zones

Distracted driving amplifies the danger exponentially. Drivers who use cellphones, adjust GPS systems, or eat while navigating work zones cannot react when traffic suddenly slows or lane positions shift without warning. The FMCSA explicitly warns against these distractions in work zones because the cognitive load of navigating unfamiliar traffic patterns leaves no mental capacity for secondary tasks. A driver’s full attention must remain on the road, the workers visible throughout the zone, and the changing traffic patterns that appear without gradual warning.

Following Distance and Rear-End Collisions

Maintaining extra following distance becomes non-negotiable in work zones since stopped or slowing traffic appears without gradual warning. Rear-end collisions represented a significant portion of fatal work zone crashes, and most of these crashes involved drivers who followed too closely to stop when traffic decelerated. Drivers must increase their following distance well beyond normal highway standards because work zone traffic patterns shift unpredictably and without the gradual deceleration that occurs on open roads.

Respecting Detours and Lane Closures

Drivers must treat detour routes and lane closures as mandatory instructions rather than suggestions they can ignore. When advance warning signs direct traffic onto detours, those routes exist because the primary path contains genuine hazards that kill people. Drivers who attempt to bypass detours by cutting through work zones or merging at the last second create the chaotic conditions where crashes happen. Lane closure signs indicating specific open lanes require immediate compliance because equipment operators and flaggers position themselves based on the assumption that drivers will follow the marked path. When drivers change lanes unpredictably or attempt to squeeze into closed lanes, they collide with workers or equipment that occupies that space.

Recognizing Workers and Flaggers as Safety Signals

Recognizing work zone signals and personnel demands active visual scanning rather than passive observation. Workers wearing fluorescent or reflective vests and positioned strategically throughout the zone serve as the final warning system before danger occurs. Flaggers holding stop signs or directing traffic with hand signals represent the absolute last line of defense against collisions. Drivers who ignore flagger signals or treat them as optional recommendations directly cause the crashes that kill both workers and other drivers. Commercial vehicle operators face heightened responsibility because large trucks and buses cannot maneuver quickly or see workers in blind spots. These operators must make eye contact with flaggers, acknowledge hand signals with clear responses, and reduce speed earlier than passenger vehicle drivers because their stopping distance extends much farther.

Final Thoughts

Road work safety depends on three groups making deliberate choices every single day. Workers must follow communication protocols, maintain visibility, and respect the traffic control plans that protect them. Equipment operators must make eye contact with flaggers, engage parking brakes, and keep vehicles within designated zones. Drivers must reduce speed, eliminate distractions, maintain proper following distance, and treat detour routes as mandatory instructions rather than suggestions.

The statistics demand action. In 2023, work zone crashes killed 898 people and injured 40,170, with construction zones accounting for 568 of those deaths. These numbers represent preventable tragedy that occurs when any group fails to execute their responsibilities. When workers operate with poor visibility, when traffic control plans sit unused, when drivers maintain highway speeds through work zones, people die-yet when all three groups function together with discipline and awareness, crashes drop dramatically and projects complete without loss of life.

Safe road work benefits everyone immediately and measurably. Workers return home to their families, drivers avoid the trauma of causing a collision, and projects finish on schedule because crews spend time working rather than responding to accidents. We at DriverEducators.com help drivers develop the awareness and skills needed to navigate work zones safely through comprehensive driver education programs designed for real-world conditions.